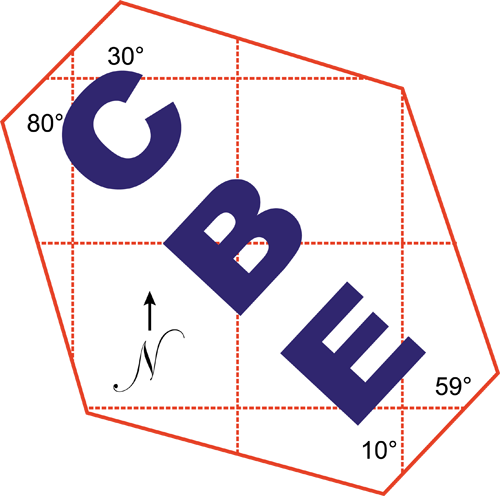

SEWERAGE TREATMENT MODULE -- CA-5

Description & Technical Specifications

Model CA-5

First introduced in 1965 to accommodate single-family home applications. Cromaglass set the standard by incorporation the Sequencing Batch Reactor (SBR) mode of operation into a Pre-Engineered, modular design for flows under 500 gallons per day. Simple, user-friendly controls, in combination with dual submersible pumps, make this the complete model for homes with 3 bedrooms or less.

DESCRIPTION CA-5

Capacity: 500 (gpd)

Dimensions (L x W x D): 7’11”x 5’ 7”x 5’ 7”

Shipping Volume 300 cf

Shipping Weight: 704 lbs

Discharge Volume: 85 gals / 6# per day

Aeration Capability 9 lbs / per 24 hrs

Control Panel 115v / 1ph / 60hz / Nema 4

Total Amps Required 15a / 120v

Electrical Consumption 8 kwh / 24 hrs

Aeration Pump(s) 1# Goulds 1/3 hp WE0311M

Discharge Pump(s) 1# Myers S25A1 (¼ hp)

SS Tie Down Rod Package 4#

Typical Cycle

FILL;

AERATION

FILL;

AERATION

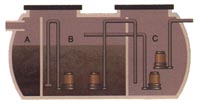

Flow enters the Solids Retention Section (A) that is separated by non-corrosive screen. Inorganic solids are retained behind the screen. Organic solids are broken by turbulence created with mixed liquor being forced through screen by submersible aeration pumps. This eliminates the need for mechanical comminution.

AERATION

Liquid and small organic solids pass through the screen into the continuing Aeration Section (B). Air and mixing are provided by submersible pumps with venture aspirators that receive air through pipe intake from the atmosphere.

DENITRIFICATION (OPTIONAL)

Provided by an anoxic period during the regular treatment cycle. Cromaglass units create anoxic conditions by closing the air intakes of the aeration pumps with electric valves. This stops aeration, but the system continues mixing.

TRANSFER/SETTLE

Treated mixed liquor is transferred by pumping to the Clarification Section (C). The transfer period overfills the Clarifier with the excess spilling through over-flow weirs back into the main Aeration Section. Transfer ceases and Clarifier ( C ) is isolated – solids separation occurs under quiescent conditions.

DISCHARGE

After settling, effluent is pumped out of the Clarifier ( C ) for discharge. Return sludge is pumped from the bottom of the Clarifier ( C ) back into the main Aeration Section (B) using a submersible pump or sludge can be wasted to a Sludge Processing Tank.